เครื่อง CNC Router ยี่ห้อ Multicam นำเข้ามาจาก USA สามารถตัดและแกะสลัก ไม้ อคิลิก และวัสดุ โลหะเนื้ออ่อน

Multicam Classic Modeling Plotter

Product Detail

High-Performance CNC Routing at an Entry-Level Price

MultiCam® accepted the industry

challenge to build a

rigid, reliable CNC

cutting machine

platform with excellent

performance at an

entry-level price.

Over 20 years of cuttingedge,

industry-leading design

experience created the MultiCam

Classic Series Router. This

machine offers a price/performance

breakthrough in CNC router design.

The MultiCam Classic Series Router is the

perfect solution for applications requiring

value, performance and price in a CNC router.

Ideal for Cutting:

• Plastics

• Non-Ferrous Metals

• Composite Materials

• Wood And More

Features

No machine in its class offers more standard features than the innovative and versatile MultiCam Classic Series Router.

• High-frequency 3-hp spindle

• EZ Control® user-friendly operator interface

• Automatic tool calibration

• High-speed three-axis motion controller

• Precision dual X-axis drives

• Cast dust collector shroud/pressure foot

• 25-mm linear bearing rails for maximum stiffness

EZ Control®

MultiCam EZ Control® is one of the most powerful yet easy-touse motion-control systems available on machine tools today. No wonder MultiCam named its motion system EZ Control!

• Hand-held operator interface with graphic icons

• 12-MB memory with unlimited file-size transfer capabilities

• Multiple home positions

• Automatic Z surfacing

• Electronic depth safety system

• Proximity restart

• Tool compensation

• Cut speed override

• Spindle rpm override

• Standard Ethernet TCP/IP connection

Spindle

Each Classic Series Router comes standard with a 3-hp, 24,000- rpm spindle and cast-aluminum dust foot. The spindle features an ER-20 collet which will handle tools up to 0.5" in diameter.

Working Surfaces

The aluminum T-slot vacuum table provides a low-cost working surface to hold parts. Or order optional phenolic grid tops with or without vacuum zoning. Choose from a selection of MultiCam vacuum pump options.

Base Frame

MultiCam fabricates the frame using aerospace-grade aluminum extrusions with integrated bearing datums. The legs are manufactured from heavy-gauge sheet steel.

Gantry

MultiCam engineered the gantry tube from aircraft-quality aluminum extrusion for maximum stiffness. Its 10-mm wall thickness ensures rigidity. References for the precision linear bearings are extruded in the design and have excellent parallelism.

Gantry Supports

Cast-aluminum gantry supports machined on a four-axis horizontal machining center guarantee perpendicularity and precision placement of linear bearings. Castings have inherent vibration-dampening characteristics and give very stiff support to the gantry tube.

Linear Bearings

The 25-mm linear bearing profile rails with stainless spring steel strip covers are standard in the X, Y and Z axes.

• High rigidity and top-load capacities in all load directions

• Lowest possible noise level and best running characteristics

• High-torque load capacity

• Four bearing packs per axis

• 4000-pound load capacity per bearing

Z-Screw Assembly

The Classic Series utilizes a ½" diameter stainless steel lead screw. For high axial force loads, a precision mounting block with dual angular contact ball bearings holds it in place firmly. A brass lead screw nut carries the Z-axis load.

Drive Motor System

For the Classic Series, MultiCam selected extensively tested two-phase, digital, brushless, synchronous electric motors. Optimized inductance and resistance of the windings provide system smoothness. Integrated digital motor drives run these motors very efficiently.

Drive Assembly

Transmissions on the X and Y axes based on a precisionmachined aluminum casting feature steel cable urethane belt drives for smooth transmission of power. A dual bearing arbor with wide bearing separation supports output pinions for optimum stiffness.

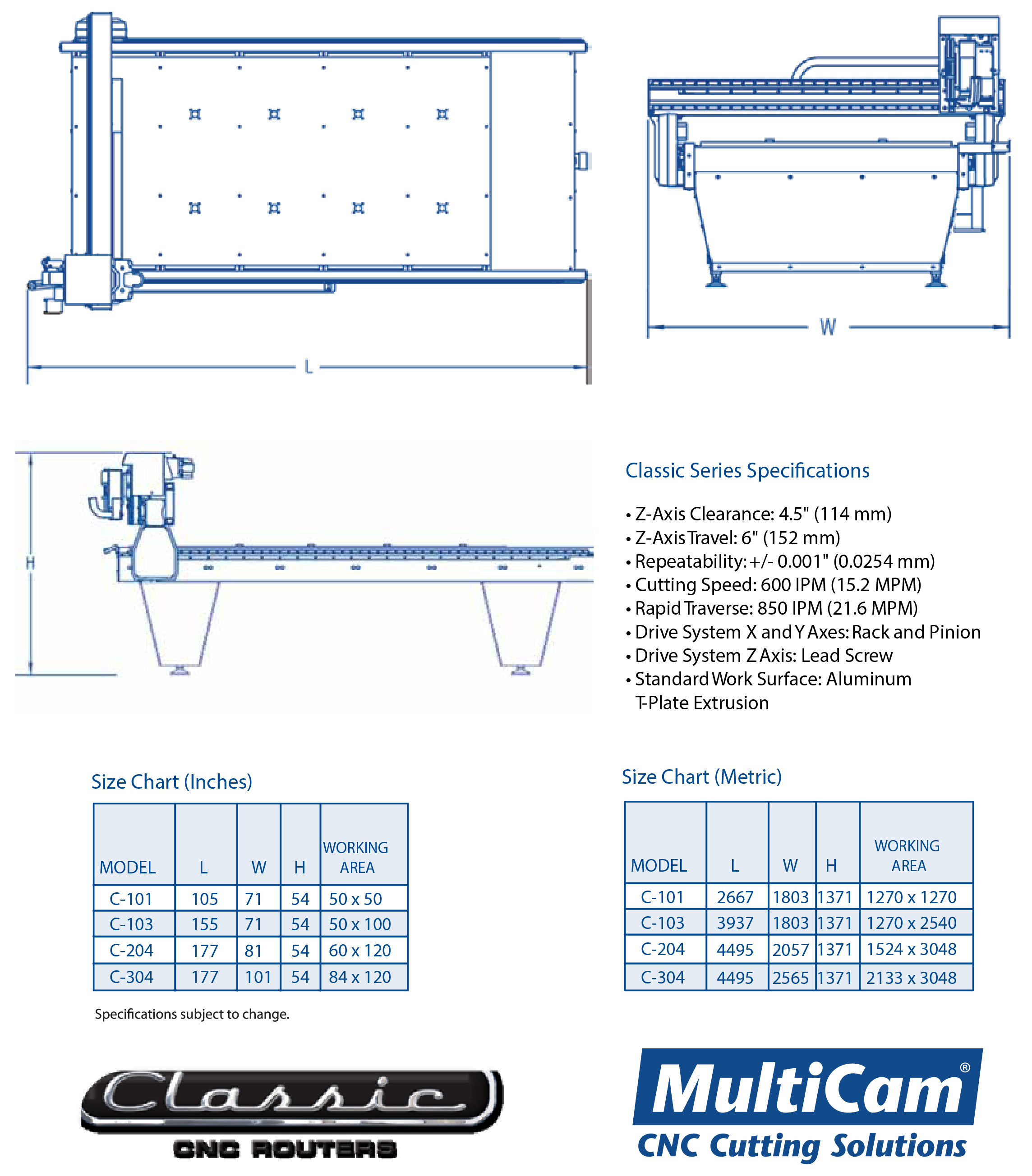

Specification

Support

- View PDF